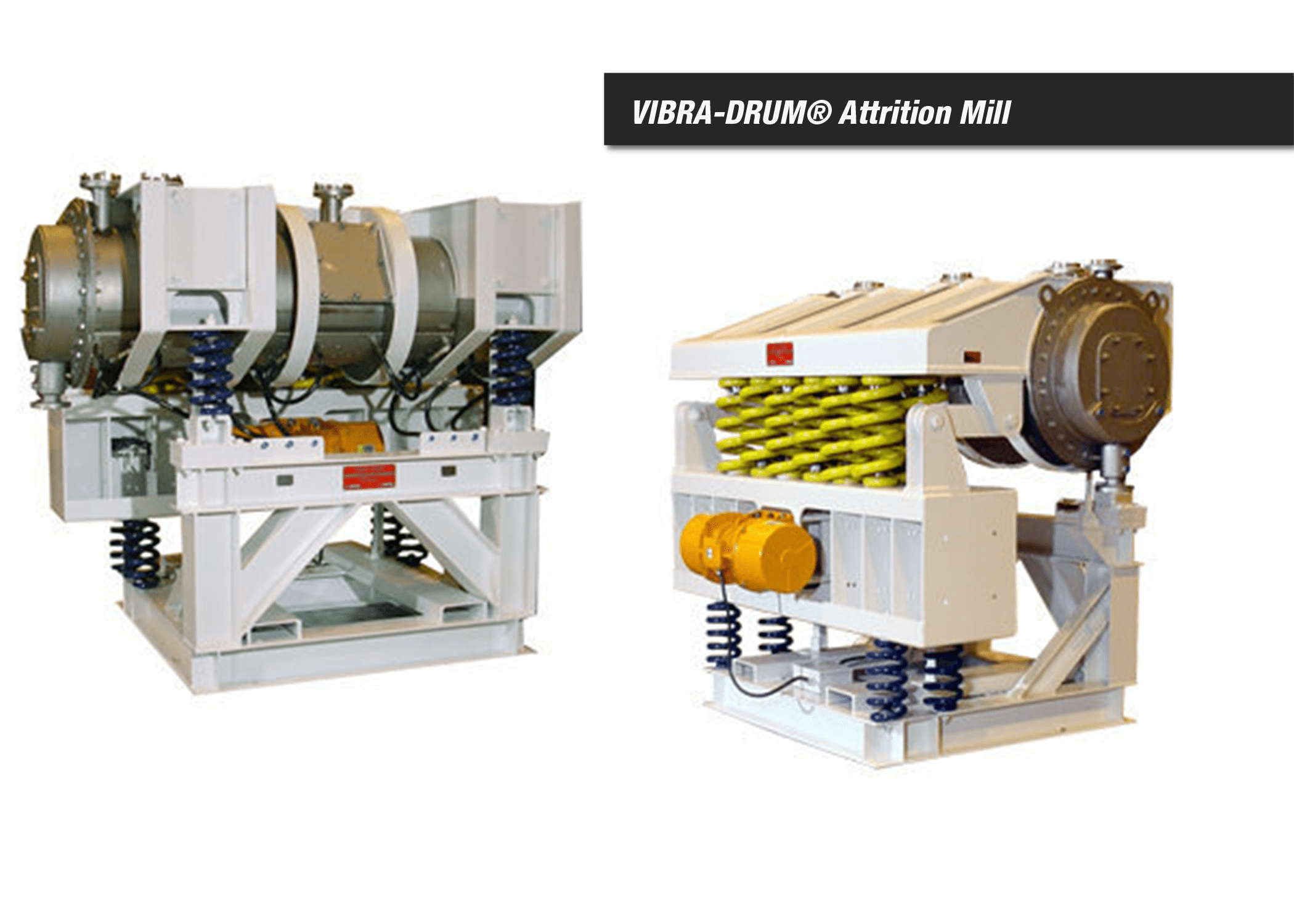

If you are looking for ways to improve your profit, reclaiming metals in your WTE plant is a great way to earn extra income. Companies that have taken on this extra earning activity have seen the rewards that it can bring, however, they are most likely not reaching the potential earning that metal reclamation is capable of. This is where General Kinematics steps in. GK has developed a VIBRA-DRUM® Attrition Mill for this application that has been showing amazing capability for return.

Fluctuation in metal prices is always changing, which makes it imperative to increase your return in any way possible. Though we have seen a rise in price late in Q1 and early Q2 we are seeing these prices drop back as a gentle reminder to reduce unnecessary spend in any way possible and increase purity to improve your yield in either situation.

GK’s Attrition Mill will increase your returns. When recovering metals from bottom ash there is a certain amount of residue left on the metal. This will negatively affect the metals in two ways: devalue in the appearance of the recovered metals, and ash will be included with the cost of shipping. Both of these will deduct from your overall profits, and who wants to pay for shipping ash?

The VIBRA-DRUM® Attrition Mill reduces the amount of remnant bottom ash drastically with a high-energy vibratory attrition action. GK’s unique attrition process provides intimate contact between the materials to provide a better scrubbing action and cleaner end product. Doing away with this excess ash lowers your cost of shipping allowing you to maximize your returns, even lowering the amount of hazardous material being shipped reducing and in some cases eliminating the associated fees.

Saving money over time is great, and the VIBRA-DRUM® Attrition Mill will help you achieve that with lower energy cost, lower shipping cost, and reduced maintenance costs. The VIBRA-DRUM® Attrition Mill uses General Kinematics’ Two-Mass Drive to provide an attrition action while furnishing energy savings of 35% up to 50%. However, who doesn’t like immediate gratification? With minimal foundation requirements, installation costs are also kept to a minimum.

Have questions about how the VIBRA-DRUM® Attrition Mill can work to increase your return on investment? Contact me!