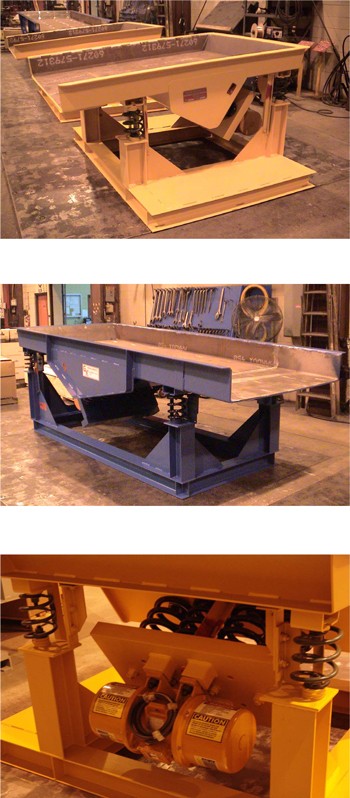

The transfer and spreading of non-ferrous auto shred residue (ASR) for better presentation to an Eddy Current Separator (ECS). Poor presentation results in ineffective separation of aluminum and auto fluff.

History:

Eddy Current’s are designed to separate aluminum from non-ferrous auto shred. This product consists of shredded metal, rubber and auto upholstery. traditional method of feed to the ECS is a vibratory, two motor, high rpm, low stroke, low energy ‘brute-force’ feeder approximately 6’ long. A rubber belt conveyor is also sometimes used. Due to the nature of ASR, transfer and spread is difficult causing a reduction in capacity. The transfer and presentation of product to the ECS is the key to better separation.

Recommendation:

Installation of the Vibratory High Stroke ECS Feeder designed with high energy for faster travel speeds resulting in improved aluminum recovery.

Summary:

Installations of the Vibratory High Stroke ECS Feeder, in the standard lengths of 6’-6″ and 12’-0″, have proven to increase the capacity by approximately 100% and improved appearance of Auto Shred Residue to an Eddy Current Separator.