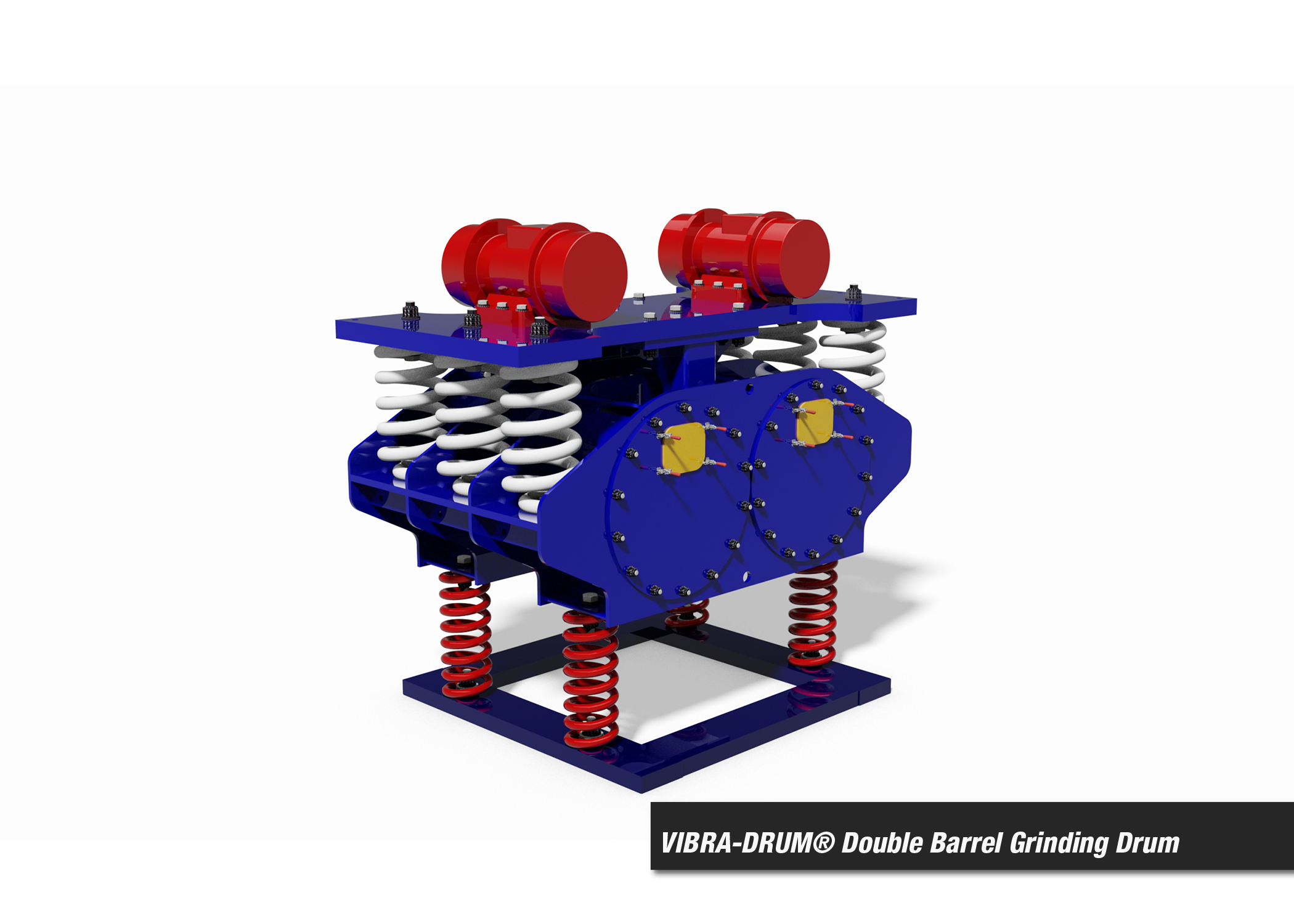

This week General Kinematics announced the VIBRA-DRUM® Double Barrel Grinding Drum. This new addition to the VIBRA-DRUM® line is the next generation of grinding drum technology, capable of breaking down materials more efficiently than single barrel grinding drum designs. Not to mention, it is energy efficient! This means you can process more for less and reduce your energy footprint.

How it Works…

The VIBRA-DRUM® Double Barrel Grinding Drum is engineered with high spring densities allowing higher energy to break down materials more effectively. The simple design, using less steel, results in lowered capital costs and smaller footprint while providing a higher capacity for your material. The VIBRA-DRUM® Double Barrel Grinding Drum breaks down your material more effectively but takes up less space in your line. With faster comminution rates and lower energy cost, GK is dedicated to increasing your return on investment.

The minus -3/8” ash material is bottom dropped through the Vibratory Rod Deck and taken out of the process. The remaining non-ferrous metals and ash are transferred by a series of GK Brute Force Vibratory Feeders before the flow is presented to an Eddy Current Separator where the non-ferrous metals are removed.

As Always…

As always with this new VIBRA-DRUM® Double Barrel Grinding Drum, you are getting a General Kinematics product which means: high quality, longevity, and a product you know you can count on. Not to mention it is backed by General Kinematics’ technical support.

At General Kinematics research and development begins with our customers. Your feedback is what drives GK to make better equipment. Our engineers are dedicated to finding new ways to make your line work for you. The VIBRA-DRUM® Double Barrel Grinding Drum was built with you in mind! Have a suggestion for future innovations? Let us know!

Interested in what the VIBRA-DRUM® Double Barrel Grinding Drum can do for your line?

Ask Our Experts!