Easy to install = More UPTIME

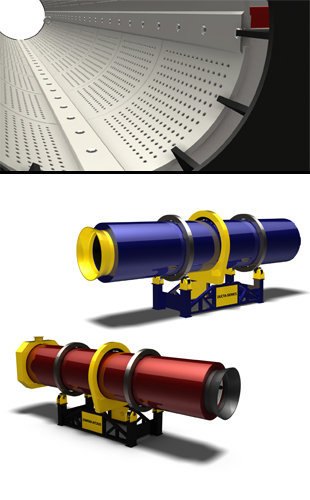

GK’s patent pending LOCK-TITE rotary drum liner system is designed to upgrade existing rotary foundry drums that utilize a cast liner. The modular system begins with a rolled AR shell to your diameter specifications. Inside, liners are held in place with GK’s proven clamp bar system which eases installation and aids in quick removal for replacement or drum maintenance. Liner systems do not require a factory trained crew to install, and can be retrofitted over a weekend.

AR Liners

LOCK-TITE liners are made from longer lasting AR wear plate materials for ultimate durability and lifespan. They also are easily customized to fit your particular process requirements.

Reduce Maintenance Costs

With the General Kinematics LOCK-TITE liners, when one panel shows wear, you can quickly replace it with simple hand tools. Since different areas of the drum will see different wear patterns, you can easily replace only the worn sections, without having to remove or replace the rest of the liner system. This significantly reduces ongoing maintenance expenditures and downtime.

Learn More!

We work hard to bring you the best foundry solutions like our LOCK-TITE liners. To learn more about GK’s rotary liners, drums, and other rotary and vibratory foundry solutions, contact a foundry specialist.