Material grinding (also called attrition milling) is the process by which materials are mechanically broken into fine granules and is an essential step in many industrial processes. Considered a subset of cutting, grinding is used in the metal-cutting process. Grinding machinery can be used to reduce the particulate size of various materials with precision, but is most commonly recognized for its uses in the mining industry where it is used to extract valuable metals, such as gold and silver, from surrounding host rock. These tools are not only useful but are also unique. For grinding materials, there are few substitutes for the high ease and efficiency of industrial grinding machines.

How do industrial grinding machines work?

Although material grinding machines are used to achieve one general purpose—physically grinding pieces of material into smaller pieces of material—there are a variety of equipment types used to accomplish this. Many mills utilize a grinding wheel which breaks material into smaller parts as it moves against the workpiece, which can also move ground material from the grinding surfaces to a collection area.

Some major types of mills used for industrial grinding include ball mills, vibratory mills, and rod mills. In addition, there are both wet and dry milling processes, which are typically chosen based on the resultant properties required for the material to be ground.

In general, the materials in attrition mills are ground via mechanical means, i.e., by physically crushing the material into smaller pieces. In ball mills, the material is loaded into a drum alongside a number of milling balls; the drum is rotated on a horizontal axis, causing the material and the balls to collide and consequently abrading the material. Vibratory mills work in a similar way, but use vibration, typically in addition to rotation, to crush the material.

Material Grinding Machines Uses

Material grinding machines can be applied to various industrial processes. As mentioned, the mining industry commonly uses milling machines to extract desired elements from the less desirable surrounding materials; however, grinding machines can be used for a variety of purposes outside of the mining industry as well. For example, mechanical attrition can be used to change the reaction of processes. For example, smaller particle size increases the surface area, which can improve the reaction speed or reduce the temperature at which a reaction occurs.

Moreover, attrition milling can be used to create nanostructured materials in a cost-effective and straightforward way. However, it’s worth noting that the creation of nanostructured materials from mechanical milling requires the consideration of the balance between the plastic deformation and the dislocation motion of the material as this can affect whether milling is an appropriate means to attain nanoscale materials.

As mentioned above for the creation of nanomaterials, some materials are difficult to grind or cut to a very fine particulate size while working with purely mechanical means. Thus, in some cases, such as for organic substances such as pigments, wet milling can be used to reduce the particle size further than possible via dry milling. During wet milling, a slurry is created. As the material is mechanically crushed, the process also disperses the material into the liquid medium. Depending on the material requirements, the liquid could be subsequently evaporated.

Find out more!

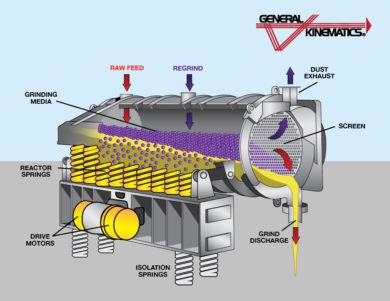

The General Kinematics VIBRA-DRUM® Grinding Mill is a high-energy vibratory drum mill that can be used to grind various materials, including cement, iron oxides, precious metals, shale, and slag. The tool offers a unique ability to recover high-value precious metals and industrial minerals that are too abrasive for other grinding technology offerings. In addition, the VIBRA-DRUM® Grinding Mill is smaller and more cost-effective than many standard single-barrel grinding drums. To find out more about this equipment or other Grinding and Attrition solutions, contact me!