For decades, service personnel at General Kinematics have been called to a customer’s facility to address mysterious running issues associated with certain GK conveyor units. After inspection, they have found the strange change in machine motion was usually a result of customers substituting replacement parts that came from manufacturers other than General Kinematics into a GK machine. This is mostly true when switching to non-GK stabilizers / rocker legs.

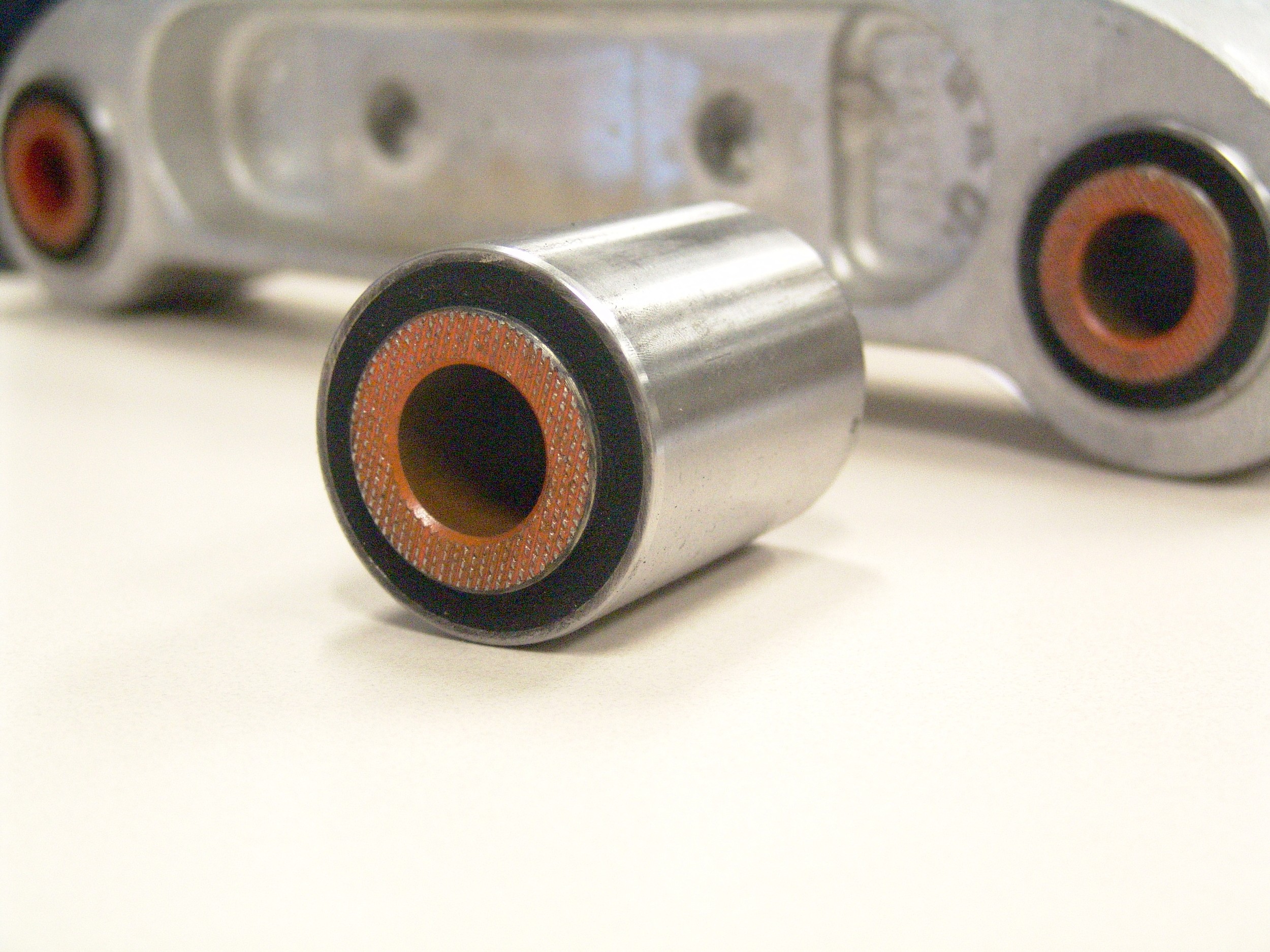

As the old adage goes, “you get what you pay for”. So holds true in vibratory component parts. To qualify that GK stabilizers are distinctly different than other bushing and leg manufacturers, lab technicians in the GK R&D Department conducted a number of specific tests to compare and contrast both the performance of bushings as well as the overall mass effect of ductile stabilizer castings versus the GK standard aluminum castings. What they found was that bushings supplied by pirate parts houses and other vibratory companies have the following inconsistencies:

- different spring rates

- different deflection rates

- different rubber compounds

- incorrect manufacturing methods which adversely effected machine performance.

Using bushings with different spring rates caused improper machine stroke, which can lead to rapid wear of components and stress to structural members on the machine itself. Improper deflection rates are caused by the wrong rubber compound, and can lead to tracking issues and increased need for re-bushing your conveyor.

Technicians also analyzed the differences between ductile iron and aluminum stabilizer legs. The immediate and obvious difference is found in the weight of the two castings. With bushings, the ductile iron leg weighed in at a stout 21 lbs. while the aluminum stabilizer weighed a much more reasonable 12 lbs. The additional weight of the ductile iron casting produced an increase in stroke on our vibratory test drive of an 1/8th inch for one leg. While that does not seem like a lot, a unit with 10+ legs can quickly operate out of spec if not retuned to function with the additional force and mass applied by these legs.

Bushing life was also compared between the two castings. Both legs were placed in our vibratory test unit and were run at a punishing stroke of 2 inches. The legs ran approximately 31 hours at this rate before the iron leg bushing failed. Upon further investigation, the difference in temperature between the aluminum leg and the steel leg was 20+ degrees F., enough to cause the bushing rubber to heat up enough to fail in the iron leg. The bushing in the aluminum leg showed no signs of wear. The resulting tests concluded that the aluminum leg significantly out performs the ductile leg in both bushing life and stroke control.

As our competition says, “not all parts are created equal”, and they are correct. Certain catalog components can be substituted into units like GK conveyors, but proprietary parts like bushings, springs, bearings and stabilizers have been proven time and again to not perform like the original equipment. All GK machines are designed with componentry that has been optimized in a certain specification range that ensures machinery performance and uptime, which can be compromised when using parts made to different standards and of different materials. For more information about GK stabilizers or any component part, contact the GK Component Sales team at 815-455-3222.