Challenge:

Challenge:

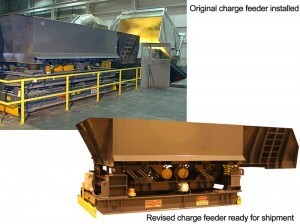

A foundry had been utilizing a General Kinematics vibrating furnace charge feeder for a number of years. With repeated drops of heavy charge material, the trough of the unit had become distorted and required refurbishment.

Approach:

The customer contacted General Kinematics and shipped the unit back to GK’s manufacturing facility in Crystal Lake, IL. After examining the machine and considering the customers material weight and volume, the engineers at GK suggested the trough be redesigned to maximize machine life and uptime.

Solution:

Using as many existing components as possible, the engineers at GK designed a new trough with significantly increased trough strength while maintaining the same functionality as the original unit.

Results:

The unit is set to return to the customer in June 2011.