Do you have a rotary drum in your foundry that is showing its age, but not ready to purchase a new one? GK’s patented LOCK-TITE™ Rotary Drum Liner Systems are designed to upgrade your existing rotary machine to the latest in rotary technology.

Reline your existing drum

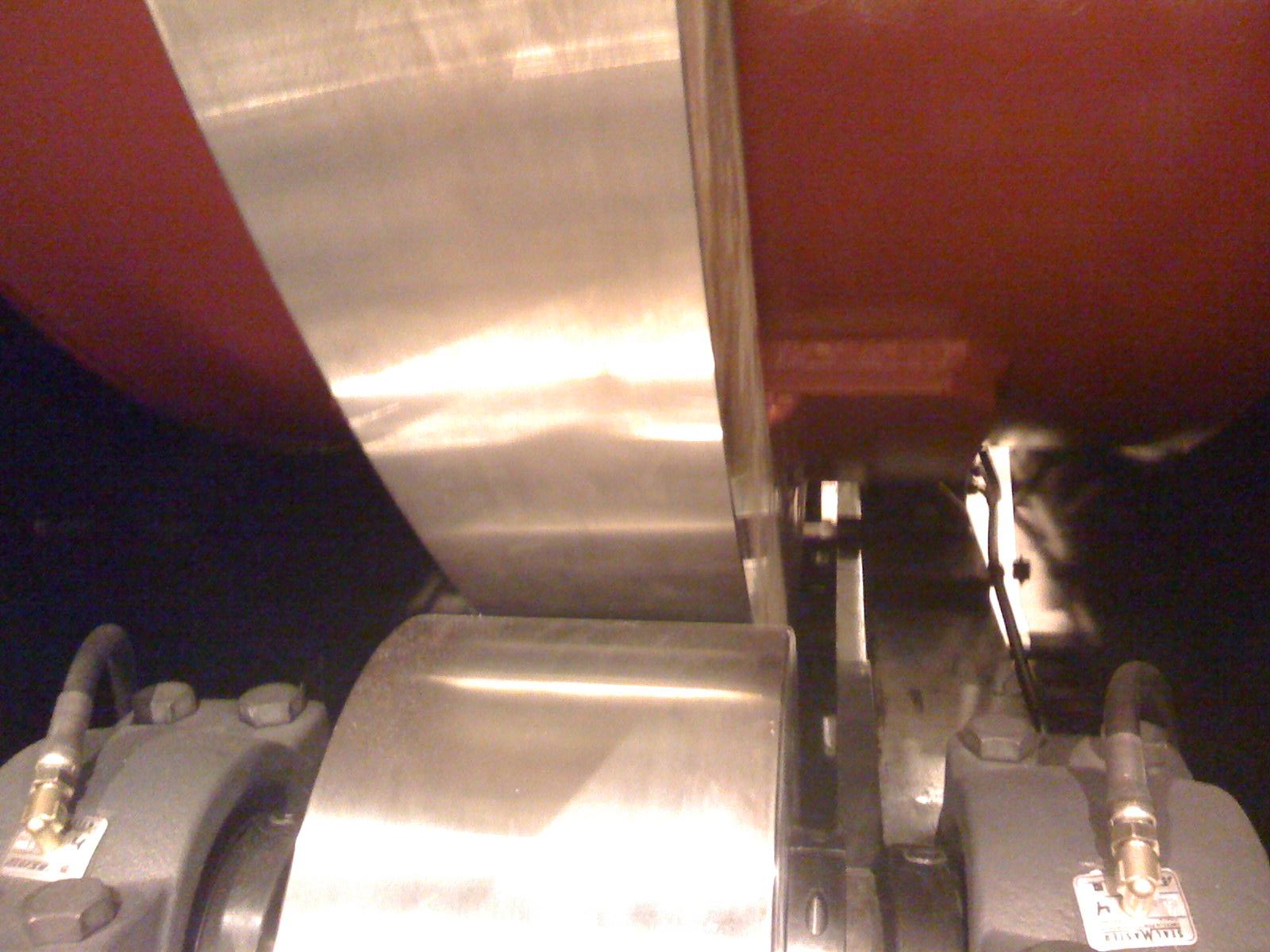

If your existing rotary drum shell is still in good shape, upgrade your liner system with GK’s LOCK-TITE™ Liners. The completely modular system is easy to install and even easier to maintain. Installation is easy using clamp bars and standard hardware. Expected installation requirements are limited to a 2 or 3 man crew with a forklift (and boom) and impact wrench for an expected change out time of approximately one to two shifts, allowing replacement to take place over a weekend. Replacing panels is as easy as unbolting and sliding a new panel in. Or, for localized wear areas, patch plates are easy to locate and weld in place directly to the liner… something you can’t easily do with other liner systems.

Advantages:

- Faster, easier, and safer to install.

- Improved inner flights and better screen design increases screening speed and efficiency.

- Modular design means you no longer have to replace your entire liner if only a small section needs replacement.

- Fabricated construction allows you to easily tweak your inner dams, rifling, and lifting lugs to tune your drum to your process… something you can’t easily do with cast grid systems.

- Optional skin liner can be installed over your existing worn drum body surface to recondition it for extended life.

- Since we fabricate each system to fit your drum and your process, we can easily change the dimensions to best suit your current processing conditions… another thing you can’t do with cast grids.