PARA-MOUNT® VIBRATING FEEDERS

Capacity Information

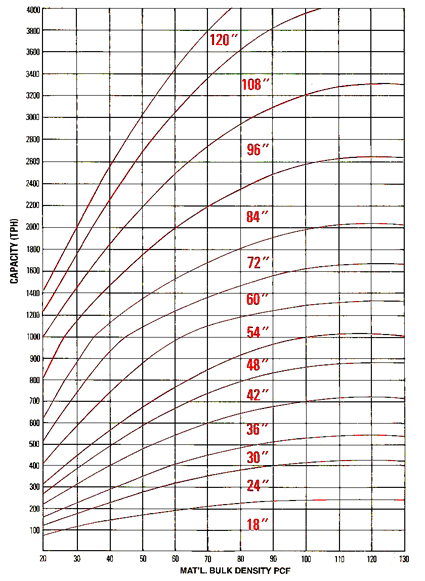

If you currently have a General Kinematics PARA-MOUNT® feeder and are looking to determine the capacity you can get out of the machine, reference the chart to the right.

Capacities shown in the chart are guides for determining the recommended trough width based upon a known bulk density and desired capacity.

As an example, consider 650 TPH of coal at 50 PCF. Extend a horizontal line from 650 on the vertical axis to meet a line extended from 50 on the horizontal axis – the intersection indicates a 60″ wide trough.

The chart should be used only as a guide since feed rates will vary with material characteristics such as particle size distribution, moisture content, angle of repose and bulk density. Maximum material travel is obtained by declining feeder consistent with hopper opening, angle of repose, and feeder length.

It is sometimes necessary to determine feeder width and length based upon the minimum hopper opening required to prevent material bridging.

If you are looking to install a PARA-MOUNT® feeder in a new application that is different from the original application it was designed for, please contact General Kinematics for installation and tuning information.