Ask the Experts

DUCTA-SERIES™ Rotary Foundry Drum

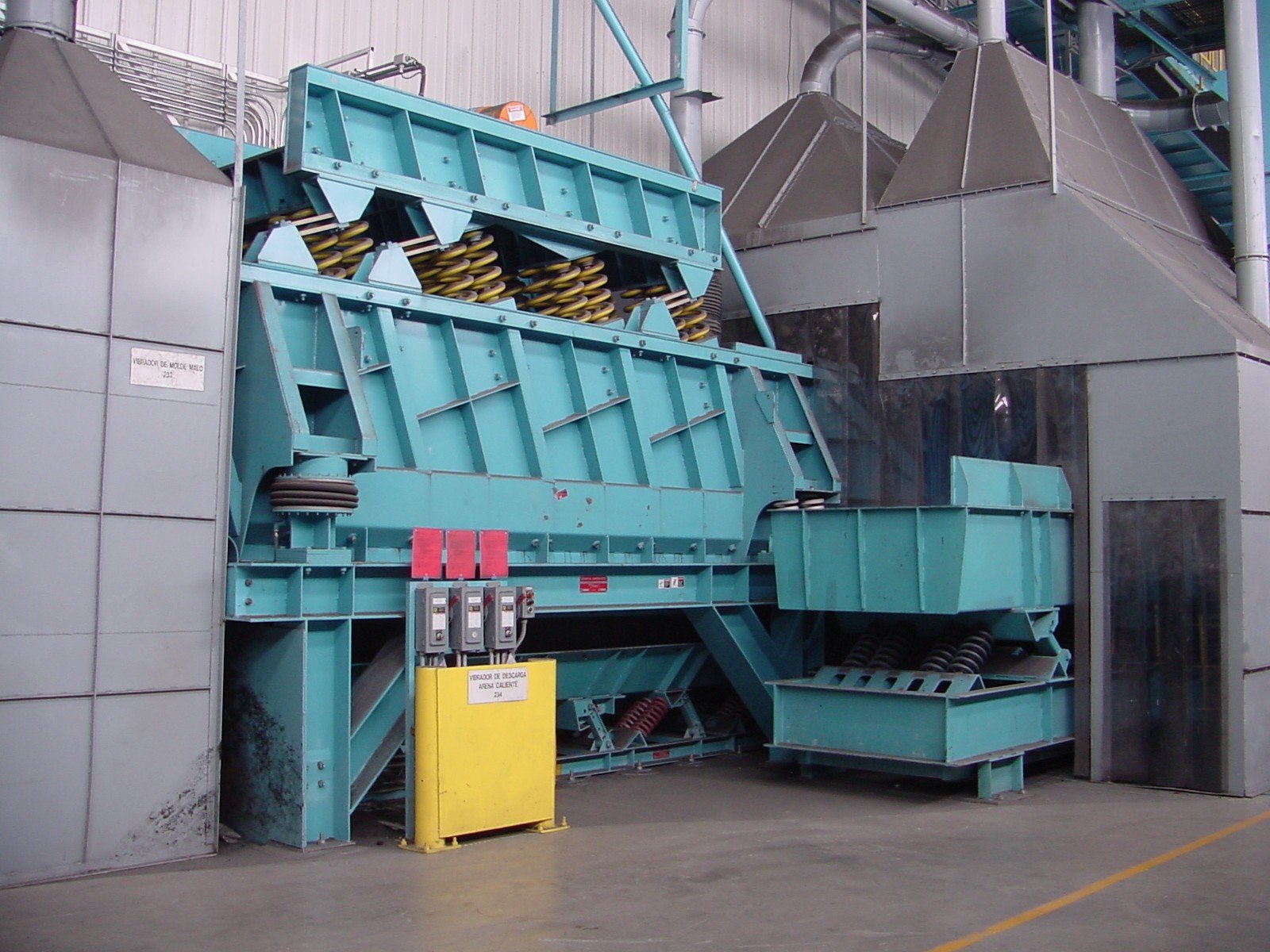

High-Performance Rotary Drums

General Kinematics’ DUCTA-SERIES™ Rotary Foundry Drums have cutting-edge rotary technology to provide a safer, low-maintenance option for any foundry process. From casting and sprue cleaning to shakeout and sand attrition, GK will design a rotary drum that meets your specific process objectives.

CUSTOMIZABLE – GK’s innovative design offers infinite liner configurations, allowing you to optimize your throughput.

SAFETY – DUCTA-SERIES™ uses positively retained liner cartridges that are easier and safer for your maintenance team to install. Drives are located at eye level.

TWO-YEAR WARRANTY – GK backs all our foundry equipment with a two-year warranty.

FEATURES:

- Classify, separate, crush, and screen sand in one efficient rotary drum.

- Available in standard and custom sizes to match your process design and throughput.

- Heavy-Duty construction ensures trouble-free operation for maximum uptime reliability.

- Installation safe LOCK-TITE Liner System.

Innovative Features, Less Maintenance, Exceptional Service

How do you make a product better? You ask the people who are using it. That is exactly what GK did when designing the DUCTA-SERIES™ line of rotary drums. Easy to service design, liners that don’t require a football team to install, and a total package concept with GK Sales and Service to back you up are just a few of the advantages GK’s DUCTA-SERIES™ brings to your foundry.

Custom Solutions Tailored to Your Process

Every foundry has unique requirements, and GK’s DUCTA-SERIES™ rotary foundry drums are customized to fit your specific process and installation needs. Whether you need to separate sand, tramp metal, or other media, GK rotary drums can be tailored to provide the most effective solution for your operation.

Superior Separation and Screening with our LOCK-TITE™ liners

Our patented LOCK-TITE™ liner system has more open area than cast grid liners, allowing faster removal of sand and tramp metal from your castings. Liners are constructed from abrasion-resistant materials, including AR 450 or optional TRI-BRAZE® wear plate, for significantly longer service life than austempered ductile liner panels. Each panel is designed to maximize service life and process throughput… no cookie-cutter cast panels that only kind of do the job. And unlike those old cast grids, if your process requirements change, you can easily modify LOCK-TITE™ liners to move, lift, and screen the way you want them to.

Do you have an existing rotary drum that you want to upgrade to use LOCK-TITE™ liners? No problem! Many of North America’s leading foundries have already switched to GK LOCK-TITE™ liners, drum bodies, and components to maximize the performance of their existing rotary drums.

Comprehensive Upgrade Kits and Components

GK offers a range of upgrade kits and components to keep your equipment running at peak performance. These include LOCK-TITE™ replacement liner kits, rotary drum body/liner assemblies, and rotary drum drive conversions. These upgrades ensure your rotary equipment remains efficient and reliable.

Applications

DUCTA-SPRUE® Rotary Sprue Mills

• Cleans and tumbles scrap, sprue, and returns

• Removes core sand and other contaminates

• Breaks down certain types of gating, runners, and risers

DUCTA-CLEAN® Rotary Media Drums

• Breaks down mold package

• Media cleans casting surface from sand and flashing

• Sand is broken down for reuse

DUCTA-SPRUE® Rotary Slag Mills

• Breaks down large slag chunks

• Recover metals

• Remove contaminates for cleaner recycle

DUCTA-SCREEN® Rotary Shakeouts

• Breaks down mold package

• Sand is broken down for reuse

• Tumbling action separates gating and sprue from castings

DUCTA-SPRUE® Sand Attrition Mill

• Aggressively breaks down sand lumps

• Batch or continuous process

• Screens metal and other contaminants from sand

DUCTA-COOL® Rotary Cooling Drums

• Tumbling action breaks down mold package

• Reduces casting and sand temperatures through evaporative cooling

• Breaks down and blends sand prior to screening